|

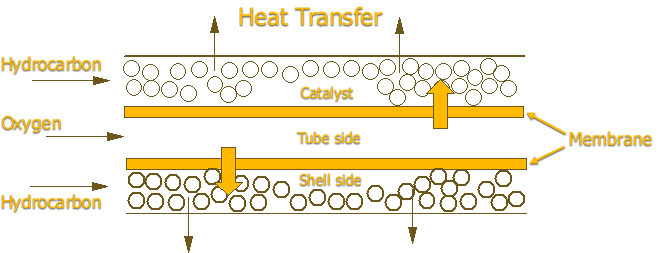

here are many possible uses of membrane

reactors to combine reaction

and separation within a single processing unit. Such uses include product removal, distributed feed

of a reactant and separated feed of two reactants, to name only some of the most-studied. Some niche

areas where membrane reactors can make a unique contribution have been identified

[Dixon, A.G., 2003]. One of these is in the control of tubular

reactor temperature profiles by distributed feed of a reactant through the reactor tube wall. here are many possible uses of membrane

reactors to combine reaction

and separation within a single processing unit. Such uses include product removal, distributed feed

of a reactant and separated feed of two reactants, to name only some of the most-studied. Some niche

areas where membrane reactors can make a unique contribution have been identified

[Dixon, A.G., 2003]. One of these is in the control of tubular

reactor temperature profiles by distributed feed of a reactant through the reactor tube wall.

Membrane reactors can be used for reactions in which the yield of an intermediate product is of

interest. A typical reaction scheme is of the consecutive-parallel type:

A + B ® R

A + R ® P + Q

where the reactions are parallel with respect to reactant A, and consecutive with respect to R.

Many catalytic reactions of commercial importance have this structure, such as hydrocarbon partial

oxidations, where A represents oxygen, B represents a hydrocarbon, R is the desired partial

oxidation product and P, Q are the undesired total oxidation products (CO2 and H2O). The general

behavior of membrane reactors with reactant feed (cross-flow reactors) under nonisothermal conditions

has been looked at in our research in the past and remains an area of interest. [Dixon, A.G.,

2001].

here are several other applications of fixed bed reactors in which CFD

may be able to play a useful role in giving a detailed picture of the transport and reaction phenomena. These include

adsorption, pebble beds in the nuclear industry, chemical looping and reforming of feedstocks other than methane. Our group is

currently carrying out studies in some of these areas. here are several other applications of fixed bed reactors in which CFD

may be able to play a useful role in giving a detailed picture of the transport and reaction phenomena. These include

adsorption, pebble beds in the nuclear industry, chemical looping and reforming of feedstocks other than methane. Our group is

currently carrying out studies in some of these areas.

|